Emulsification

PART IV

The process of

emulsion formation is known as ‘Emulsification’.

Emulsification is

the dynamic and non spontaneous process and energy is required to produce the

product (emulsion).

It requires

considerable amount of mechanical energy to disperse one liquid phase into

another.

By using various

techniques and machinery, the huge droplets are converted into small droplets I.

e. droplet deformation, by using fundamental shearing force and centrifugal

force.

For formation of

emulsion three condition must be fulfilled –

a)

Existence of surfactant

b)

Immiscibility

c)

Agitation

To form a stable

emulsion, an emulsifying agent must be added to the system.

v Theories of Emulsification :-

The theories of

Emulsification are used to describe the action of emulsifying agent in the

emulsion system.

They affects the

interface in such a way that to obtain a stable emulsion.

A)

Surface

tension theory-

Molecules in a

liquid are attracted equally on all the sides by the surrounding molecules, at

surface there is an inward attraction of molecule due to inward force of

attraction.

Due to this

attraction, a stress is produced at the surface of the liquid is known as

surface SURFACE TENSION.

When two immiscible liquid

comes in contact ,the force causing each liquid to resist breakage is known as INTERFACIAL

TENSION.

Let us consider the

three molecules A, B, and C.

The molecule A is

present in the deep inside of liquid. A molecule B is present just below the

uppermost layer of the liquid and molecule C is present at the uppermost layer

of the liquid.

The molecule A is

present in the deep inside liquid is stable because that molecule is attracted

equally from all the sides. Thus, it is stable.

The molecule B is

present just below the uppermost layer of the liquid, so it tends to be appear

a slight unstable as from one side it is not attracted by another molecule.

But the molecule C,

the force of attraction is only by one side so it has more tension towards down

and it appears to be stretched the whole layer.

The emulsifying

agent cause lowering of interfacial tension and also decrease the repulsive

Forces between the two cohesive molecules.

As a result, the

emulsifying agent tends to cause breakage of large molecules into small.

B)

The

oriental wedge theory of emulsion :-

According to the

oriental wedge theory of emulsion, oil like or non polar ends up emulsifying

agent turns towards the polar liquid.

This theory also

indicates that if the non-polar end of emulsifying agent is smaller, the emulsion will be oil in water (o/w) and

if polar end is smaller, the emulsion will be water in oil (w/o).

C)

The interfacial film theory :-

The interfacial film

theory suggests that the emulsifying agent make an interface between the two

immiscible phases of the emulsion, surrounding the droplets of the internal

phase as the film.

This film prevents

the coalescence of the emulsion.

D)

One theory can also be explained, like when the emulsion is passed through

mixers or agitators the mixer rotate in circular motion so on each molecule the

centrifugal force will occur and tends to get divided into small droplets.

·

Emulsification

methods:-

1.

Oil in

water emulsion:

Initially, the oil

phase is completely converted into small molecules, in advance with formation

of film by emulsifying agent according to interfacial film theory.

Finally, the oil

phase with surfactant are added into aqueous phase to create a oil in water

emulsion.

Generally, a

surfactant removes the excess of energy at oil – water interface and make

emulsification easier.

But this challenges

the physiochemical properties of surfactant and entire system.

Eg- In PIT system

with low interfacial tension tends to very fine emulsion and self emulsification.

At higher

temperature close to PIT, it tends to coalgulates and generally gets separated

into two phases.

At last for making

an effective oil in water emulsion it has to utilize low interfacial tension

and surfactant molecules should adsorb easily.

The preparation of water in oil emulsion are same as those of oil in water emulsion but the repulsive forces cannot be achieved in water in oil emulsion because oil is in continuous phase.

Infact it becomes difficult to achieve stabilization in water in oil emulsion by adsorption of surfactant at oil water Interface, because the quantity of surfactant dissolved is much higher in oil phase in water in oil emulsion.

Thus, it results into foaming and unpleasant taste of an emulsion.

To avoid this, a viscosity of dispersed phase should must be increased by adding amino acids and clay minerals.

A reverse hexagonal liquid crystal can also be an option.

The water in oil emulsion have separate emulsifiers like silicone oils, polyether modified silicone emulsifier.

They just improve the stability of low viscous water in oil emulsion by using polyether modified silicone.

3. High internal phase ratio emulsion (HIPRE) :-

Their defining feature is an internal phase volume ratio of 0.74 or greater, which means a volume of an emulsion comprising droplets.

The value of ¢ means maximum volume ratio of uniform no deformable spheres when packed in most efficient manner.

( For this please refer Augustus Bravis solid state configuration).

HIPRE can forms mist flexible and uniform droplets upto ¢ = 0.99

It has used to form oil in water emulsion with high internal phase ratio by using viscous liquid cubic crystals.

4. Multiple emulsion:-

The reason why the multiple emulsion are topic of interest in people? Are follow-

i. Delivering drugs to specified targets in the body without possible deleterious effect of these drugs on other drugs.

ii. Prolonging the release of drugs have short half life.

iii. Creating a novel texture on breaking the multiple drugs.

The multiple emulsion can be prepared by two methods-

• One step procedure

• Two step procedure

The multiple emulsion like water in oil in water are prepared by two step procedures, like a performed water in oil emulsion is added into an aqueous solution with hydrophilic emulsifying agent.

One step procedure can be done by using the phase inversion method.

The drawbacks are same composition between internal phase and external phase and undefined amount of active encapsulated in emulsion droplets.

The advantages are-

a) Simple handling

b) High production rate.

To stabilize the multiple emulsion use several surfactant and using D phase emulsification method.

5. Surfactant free emulsion (sf- emulsion) :-

Surfactant free emulsion can be defined as an emulsion stabilized without any surfactant by using ultrasonic radiation ranging from 10 -1000 KHz to mixture of water in oil.

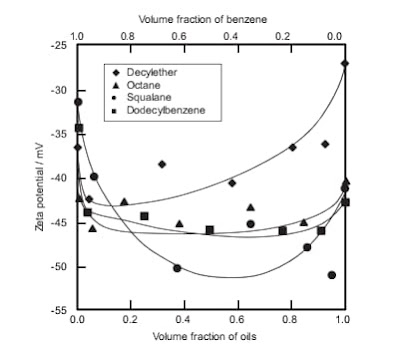

Ultra sonication generates active oxygen species such as OH and H2O2 which alters the charges on water oil interface, changing them to negative zeta potential.

In case of non polar oil, stability of sf- emulsion is improved by using higher hydrocarbons especially alkanes which makes oil droplets small upto 100nm.

The instability can occur at lower alkanes chain like at (C6- C16) .

6.Bottom up emulsification:-

It is the process in which a homogenous solution and solutes are allowed to assemble nanoparticles.

They use nanoemulsion phase as homogenous base.

The novel bottom up emulsification are performed under high pressure and temperature which results into homogenous solution if nanoparticles.

Eg- A fine mono dispersed nano emulsion can be produced when quenching rate is more than 200°C /sec.

6. Emulsion prepared by hybrid type polymer:-

The amphilic polymer such as AIM ( active interfacial modifier) can stabilize oil in water interface.

The AIM consists of silicone molecule bonded with hydrocarbon and hydrolyzed silk peptides with selective solubility.

This property cause preferential localization of the polymer at oil water interface leading to high stability of the interfacial phase. Addition of AIM to a mixture of water and silicone oils gives stable mono dispersed water in oil emulsion in a wide range of composition by small energy input such as gentle agitation by a Vortex mixer.

Unlike general emulsification, there are no significant reduction of oil water interfacial tension, but AIM preferential localization at water oil interface prevents coalescence to maintain stable emulsion fir long period.

7. Three phase emulsion:-

Soft hydrophilic nano particles adheres firmly to the interface of oil droplets through van der Waals interaction between the nanoparticles and oil droplets, resulting in formation of stable emulsion.

This emulsion is known as “three phase emulsion “ and often uses self assembly or polycondensation polymer as the soft nano particle.

Stability of this emulsion can be independent if the kind of oil, in contrast to the general surfactant based emulsion.

Good content

ReplyDeleteThank you very much stay tuned for more freshly brewed pharma content.

ReplyDelete